When choosing a professional ladder, several key factors should be considered to ensure safety and efficiency. The nature of the work, the height required, and the weight capacity are crucial elements to consider.

Material Selection for Professional Ladders

Aluminum Ladders: Advantages and Applications

Aluminum is a common material for ladders because it is lightweight and yet very strong. The main part has the characteristics of aluminum alloy as light-weight, high strength and high corrosion resistance. Because of this, they are great for both indoor and outdoor jobs. Aluminum ladders are also easy to transport and store, an essential aspect for professionals.

Steel Ladders: Strength and Heavy-Duty Use

Steel ladders, known for their sturdiness & ruggedness, are designed for heavy-duty use. They build strong and withhold a lot of weight which makes them a necessity in industrial units, be it a construction site or a manufacturing plant. Steel ladders weigh more than aluminum options, but they provide incredible stability and near-unbeatable wear resistance after years of use.

Ladder Types and Their Specific Uses

Step Ladders for Versatile Applications

Step ladders have an A-frame shape and are one of the most versatile types of ladder. They offer a stand-alone feature with no wall anchoring needed. These ladders are ideal for jobs where you need to reach moderately high, like putting up lights or washing windows. They take up hardly any space, which makes it easy to store and transport them.

Extension Ladders for Height Accessibility

Extension ladders telescopically extend to allow you to reach high places. There will work more specifically suited for open-air construction or high-up projects. Even professionals should follow safety measures, such as maintaining a 75-degree angle with the ground to ensure the gear is stable while being used.

Specialty Ladders for Unique Work Environments

Specialty ladders are used to meet special requirements in certain working conditions. Some, such as the insulated fiberglass ladders needed by electricians, are non-conductive and this is essential. Platform ladders also offer a large stable work surface at height and are best for jobs such as painting or assembly work that take a while.

Load Capacity and Weight Ratings of Ladders

Importance of Load Ratings in Professional Use

Load capacity is a critical factor in ladder selection. Professional-grade extension ladders often use thickened aluminum alloy profiles that can withstand several hundred kilograms. Overloading a ladder can lead to structural failure and severe accidents.

How to Match Load Capacity with Job Requirements

Finally, to match the job to a ladder’s load capacity, combine the weight of the user, tools, and materials being carried. Select ladders with high weight ratings based on standard household limits of 150 kilograms, especially for heavy-duty industrial applications.

Safety Features in Professional Ladders

Anti-Slip Steps and Feet for Enhanced Safety

The anti-slip step and foot will help reduce the chances of serious injury from falls resulting from slip-ups, giving your clients the grip they need. While the surroundings are wet or oily, the wide anti-slip pedals give no chance to slip and are comfortable enough for long hours of use.

Locking Mechanisms for Stability During Use

Modern professional ladders incorporate advanced locking mechanisms that enhance stability during operation. These features ensure that telescopic sections remain securely in place, preventing accidental collapses that could lead to injuries.

Discover JADDUO for premium ladder solutions that suit your professional needs. By incorporating the latest research and designs while meeting world-class safety standards such as EN131 certification, JADDUO delivers the reliability you can count on.

Ladder Height and Reach Considerations

Determining the Optimal Ladder Height for Tasks

Choosing the right height for a ladder is essential to safety and workflow. Each ladder type has its own guidelines to make sure it can be used safely. Standing on the second from the top step is the maximum safe reach height for A-frame ladders.

You can comfortably reach the maximum height of the safe range between the fourth and top rung. Not taking the first three steps avoids unsteadiness and danger. Straight ladders should be approximately 0.5 m less than your working height. That is, a task at a 4-meter height would need a ladder with a height that is more than 3.5 meters.

Factors Affecting Maximum Reach

Any ladder has a maximum reach determined by a few variables: user height, distance between rungs, and ladder type. When performing outdoor jobs, the way the grounds are — uneven ground — might call for an additional level of height buffer to maintain stability.

User behavior is another factor, for instance, against going overly far and disappearing into the distance. To really mitigate these risks, you always want to be aligned between the rails.

Portability and Storage of Professional Ladders

Lightweight Designs for Easy Transportation

Today’s work site ladders are built to maximize portability while maintaining strength and durability! Aluminum ladders offer notable advantages over other varieties due to their lightweight and resistance to corrosion.

This is also one of the main reasons why those kinds of professionals read these types of tools they are designed for moving between these job sites a lot.

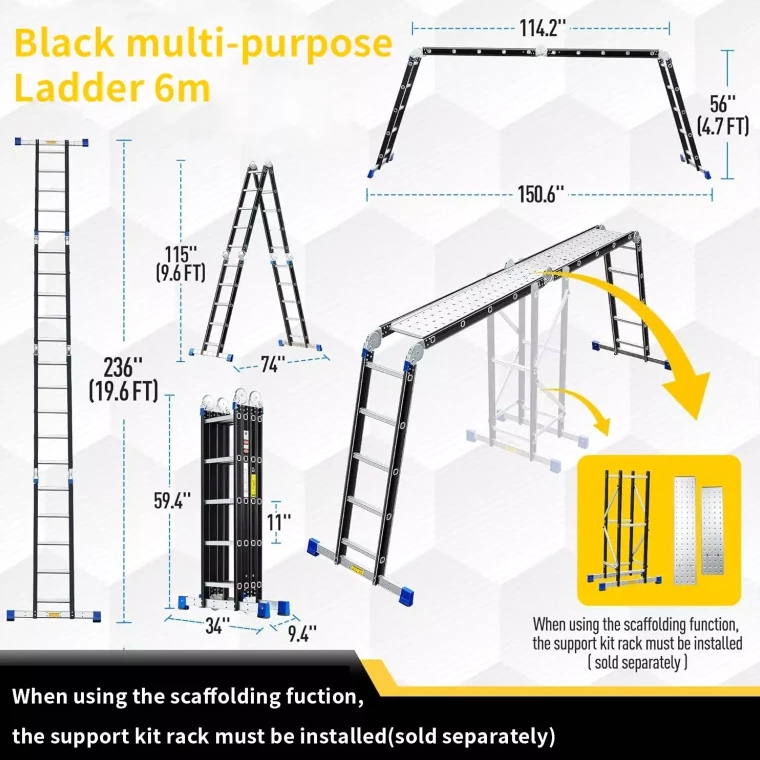

Foldable Options for Space-Saving Storage

Along with offering solutions for vertical ascent, these professional ladders feature foldable designs that help save space and provide easy storage in compact areas, such as workshops or vehicles.

For this reason, telescopic ladders have an upper hand as they come to a compact shape after use. Not only does it make transport easier, but also helps to avoid accidents by storing unnecessary ladders properly.

JADDUO’s Ladder Solutions and Recommendations

Premium Aluminum Models from JADDUO

JADDUO can be trusted with the right solution of premium aluminum ladders made from 6063-T5 high-grade aerospace aluminum alloy which are rust and wear-resistant, specially designed for professionals especially when light weight is desired.

Blending functionality with safety features such as anti-slip feet and reliable locking mechanisms to ensure consistent performance in a range of applications.

JADDUO Fiberglass Options Designed for Professionals

A fiberglass ladder provides electrical safety, making them essential in a wide range of industries. Their resistance to conductors makes them useful. JADDUO’s fiberglass options are designed for heavy-duty reinforced construction yet conform to rather high safety standards

Specialized JADDUO Ladders Tailored to Industry Needs

At JADDUO, they also offer customized solutions built for specific industries to address unique requirements. Whether you want platform style for long-running jobs or OEM/ODM design that fits specific demands, they cover the need spectrum quite well for professionals.

FAQs

Q1: How do I choose between aluminum and fiberglass ladders?

A: Aluminum is lightweight and versatile for general use, while fiberglass offers non-conductive properties essential for electrical work.

Q2: What features enhance ladder portability?

A: Lightweight materials like aluminum and foldable or telescopic designs improve portability and ease of storage.

Q3: Why should you avoid standing on the very top rungs of a ladder?

A: Walking nearest to the peak also jeopardizes stability, virtually inviting a tumble off the edge.